Why Garage Door Maintenance Lubrication Is Essential

Garage door maintenance lubrication is one of the simplest yet most impactful tasks you can perform to keep your door running smoothly, quietly, and reliably for years. Without it, metal-on-metal friction wears down springs, rollers, and hinges—leading to grinding noises, jerky movement, and eventually, costly breakdowns that require attention from a professional garage door company. Proper lubrication is a core part of maintaining your home’s largest moving object and fits right alongside regular garage door service and repairs as essential preventative maintenance.

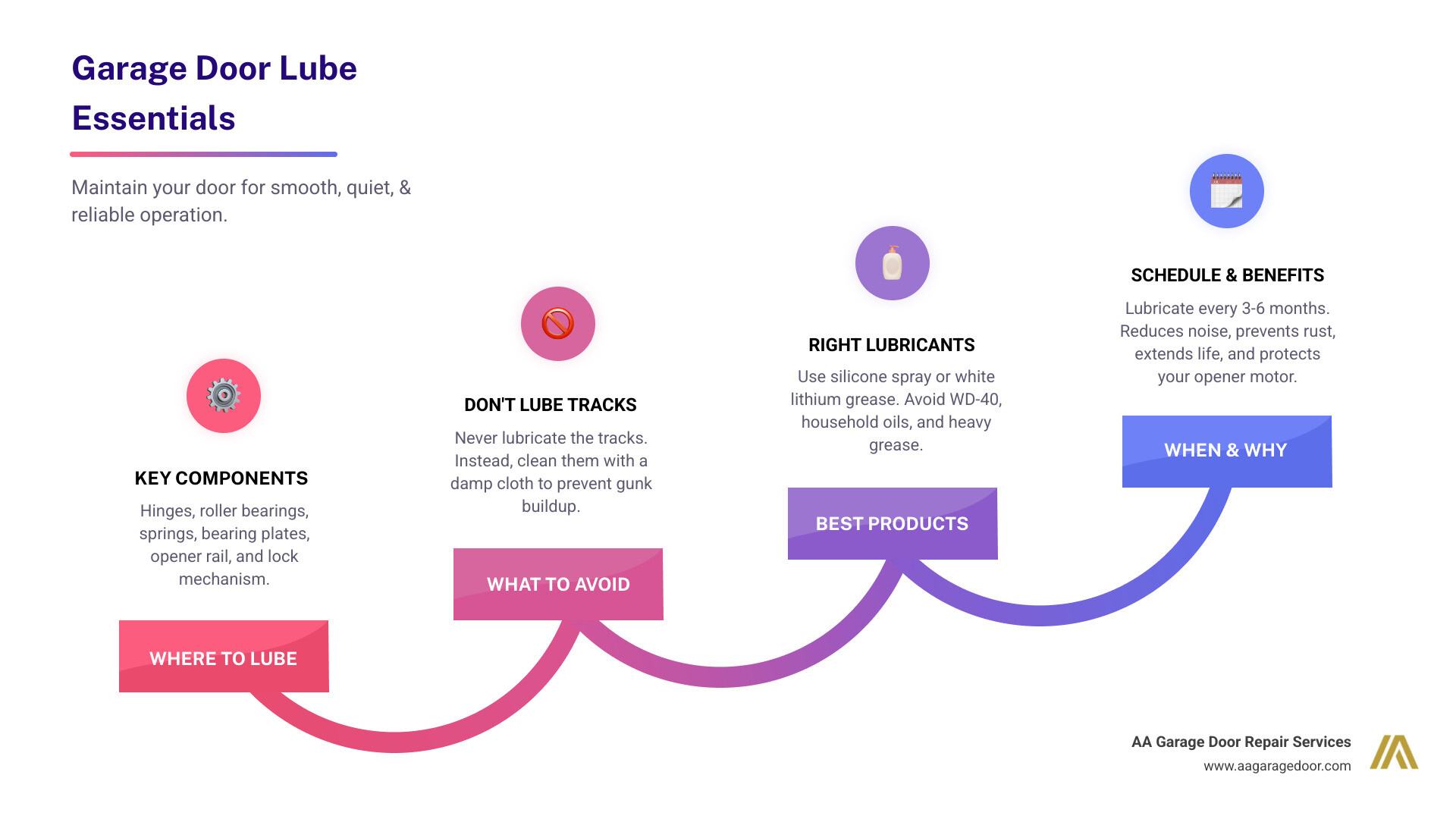

Quick Answer: Garage Door Maintenance Lubrication Essentials

- What to lubricate: Hinges, roller bearings, springs, bearing plates, opener rail, and lock mechanism

- What NOT to lubricate: Tracks (clean them instead)

- Best lubricants: Silicone spray or white lithium grease

- Avoid: Standard WD-40, household oils, and heavy grease

- How often: Every 3-6 months (twice yearly in harsh climates)

- Benefits: Reduces noise, prevents rust, extends component life, protects your opener motor

If you notice squeaking, grinding, or hesitant movement, your door is overdue for attention. Regular lubrication takes just 15-20 minutes and can prevent emergency garage door repairs that cost hundreds or thousands of dollars.

I’m David Sands, owner of AA Garage Door LLC, and over 23 years of serving homeowners across Wisconsin and Minnesota, I’ve seen countless preventable failures caused by skipped garage door maintenance lubrication. This guide will show you exactly how to do it right, using the same techniques our certified technicians follow in the field.

Must-know garage door maintenance lubrication terms:

- do garage doors need maintenance

- how often do garage doors need maintenance

- garage door opener maintenance

Why Lubrication is Non-Negotiable for Your Garage Door’s Health

We often take our garage doors for granted until they start complaining. That squeak, that grind, that hesitant movement – it’s your garage door literally crying out for some love. And that love, more often than not, comes in the form of proper garage door maintenance lubrication. It’s not just about silencing annoying noises; it’s about safeguarding a complex system that works hard for you every day.

Here’s why garage door maintenance lubrication is absolutely non-negotiable for your door’s health and longevity:

- Friction Reduction: At its core, lubrication reduces the metal-on-metal friction inherent in a garage door’s operation. When hinges pivot, rollers glide, and springs stretch and contract, friction is at play. A good lubricant creates a thin, slippery barrier that allows these components to move against each other with minimal resistance.

- Noise Elimination: Reduced friction directly translates to a quieter operation. Lubricating the moving parts helps eliminate those irritating screeching, grinding, and rattling sounds that can echo through your home. A quiet door is a happy door, and a happy homeowner!

- Rust and Corrosion Prevention: Many garage door components are made of metal, making them susceptible to rust and corrosion, especially in climates with harsh winters or high humidity, like here in St. Paul and Western WI. Lubricants form a protective barrier against moisture and environmental contaminants, preventing rust from taking hold and degrading your components.

- Extends Component Lifespan: Regular garage door maintenance lubrication helps prevent premature failure of key components like rollers, hinges, and springs. By minimizing wear and tear, you significantly extend the working life of these parts, saving you money on replacements down the line.

- Reduces Strain on Opener Motor: When moving parts are stiff and resistant, your garage door opener has to work much harder to lift and lower the door. This added strain can prematurely burn out the motor, leading to an expensive opener replacement. Lubrication ensures the door moves freely, easing the burden on your opener.

- Prevents Premature Failure: By keeping everything moving smoothly, lubrication acts as a preventative measure against unexpected breakdowns. It’s a simple, proactive step that can save you from the inconvenience and cost of a door that suddenly stops working.

Consequences of Neglecting Garage Door Lubrication

Ignoring garage door maintenance lubrication is like skipping oil changes for your car – it might seem fine for a while, but eventually, you’ll pay a much higher price.

- Increased Wear and Tear: Without lubrication, metal parts grind against each other, leading to accelerated wear. This isn’t just cosmetic; it weakens the structural integrity of components.

- Costly Garage Door Repairs: A neglected door is a ticking time bomb for repairs. Worn rollers can pop out of tracks, stiff hinges can break, and overworked springs can snap. These issues often require professional intervention and can be far more expensive than routine lubrication.

- Potential for Sudden Breakdown: The worst-case scenario is a sudden, unexpected breakdown. Imagine needing to leave for work only to find your garage door stuck halfway open or completely jammed. Not only is it inconvenient, but it can also pose a security risk.

Choosing the Right Products for Garage Door Maintenance Lubrication

The type of lubricant you use is just as important as the act of lubricating itself. Using the wrong product can actually do more harm than good.

Best Lubricants:

For optimal garage door maintenance lubrication, we recommend specific types of lubricants designed for this application:

- Silicone Spray: This is a top choice for many garage door components. Silicone sprays penetrate deeply, offer long-lasting lubrication, and, crucially, do not attract dirt and dust. This makes them ideal for parts that are frequently in motion.

- White Lithium Grease: This type of grease is excellent for metal-on-metal contact points, offering robust, long-lasting lubrication. It’s particularly good for screw drives or roller stems. However, be mindful that thicker greases can coagulate and clump over time, especially in very cold climates like ours.

- Specialized Garage Door Lubricants: Many manufacturers offer products specifically formulated for garage doors. These are often a blend of silicone or lithium. For example, Clopay Synthetic Pro Lube for Garage Doors 4128043 is a good example of a synthetic, anti-friction formula.

Lubricants to Avoid:

- Standard WD-40: This is perhaps the most common mistake we see. While WD-40 is a fantastic water displacer and solvent, it is not a long-term lubricant. It can strip away existing grease, attract dirt, and dry out quickly, leaving your components more vulnerable than before. Think of it as a cleaner, not a lube.

- Household Oils (e.g., 3-in-1 oil): These oils are generally too thin and will quickly run off, offering minimal lasting lubrication. They also tend to attract dust and grime, which can turn into an abrasive paste.

- Heavy Grease (on tracks): While some components benefit from grease, applying heavy grease to garage door tracks is a big no-no. It will attract dirt, dust, and debris, causing rollers to stick or bind, and ultimately hindering the door’s operation.

TABLE: Silicone Spray vs. White Lithium Grease for Different Parts

| Component | Silicone Spray (Best for) | White Lithium Grease (Best for) |

|---|---|---|

| Hinges (pivot points) | Excellent (clean, non-dirt attracting) | Good (durable, especially for metal hinges) |

| Rollers (bearings/stems) | Excellent (penetrates bearings, doesn’t attract dirt) | Good (durable for metal stems, can be thick for bearings) |

| Springs (torsion) | Excellent (coats evenly, protects against rust, repels moisture) | Not ideal (can be too thick, attract dirt to coils) |

| Opener Rail (top) | Good (clean glide for trolley) | Good (durable, can be used for screw drives) |

| Opener Chain/Screw Drive | OK (may require more frequent application) | Excellent (designed for chains and screw mechanisms) |

| Bearing Plates | Good | Excellent (for robust, long-lasting protection) |

| Locks/Latches | Excellent (clean, non-gumming for intricate mechanisms) | Not ideal (can gum up small lock mechanisms) |

| Tracks | NEVER | NEVER |

Safety First: Essential Precautions

Before you begin any garage door maintenance lubrication, safety must be your absolute priority. Garage doors are heavy, complex pieces of machinery with powerful springs under immense tension. Mishandling them can lead to serious injury.

Always follow these safety precautions:

- Disconnect Power: The very first step is to unplug your garage door opener from the electrical outlet. This prevents accidental activation while your hands are near moving parts.

- Engage Manual Release (Carefully): If your door is connected to an automatic opener, use the emergency release cord to disengage it. This allows you to move the door manually if needed, but be aware that if your springs are broken, the door can slam down.

- Secure the Door: If you plan to work on the springs or other components that might cause the door to move, place a C-clamp or vice grip on the track just above a roller to prevent the door from accidentally closing.

- Use a Sturdy Step Ladder: Never stand on unstable objects. A sturdy step ladder is essential for reaching higher components safely.

- Wear Protective Eyewear: Lubricants can spray, and dust or debris can fall. Safety glasses are a must to protect your eyes.

- Wear Gloves: Gloves protect your hands from grease, grime, and potential cuts from sharp edges.

- Proper Ventilation: If using aerosol sprays, ensure you have good ventilation in your garage to avoid inhaling fumes.

- Keep Children and Pets Away: Ensure no children or pets are in the work area. A garage door can be dangerous, and you need to be able to focus without distractions.

The Ultimate Guide to Garage Door Maintenance Lubrication

This section provides a definitive, step-by-step process for lubricating all necessary components of your garage door system. Following these steps ensures a quiet, efficient, and long-lasting door.

Step 1: Gather Your Tools and Clean the Components

Preparation is key to effective garage door maintenance lubrication. Before you even think about spraying, you need to get your workspace ready and your components clean.

- List of Tools:

- Silicone-based spray lubricant or white lithium grease (in spray form for easy application)

- Clean rags (several, to wipe off excess and clean)

- Sturdy step ladder

- Safety gear (gloves, safety glasses)

- Optional: Small brush, automotive brake cleaner (for stubborn grime)

- Cleaning Process:

- Wipe Down All Moving Parts: Before adding new lubricant, it’s crucial to remove old, gunked-up grease, dirt, and debris. Use a clean, dry rag to wipe down hinges, rollers, and springs.

- Remove Old Gunk and Debris: Old lubricant can attract dust and turn into an abrasive paste, which is counterproductive. Pay special attention to the pivot points of hinges and the bearings of rollers.

- Use a Damp Cloth: For general dirt on components, a damp cloth can be effective.

- Automotive Brake Cleaner for Stubborn Grime: If you encounter really stubborn, caked-on grease on metal parts (like roller stems or hinge pins), a small amount of automotive brake cleaner can be used to loosen and remove it. Be sure to use it in a well-ventilated area and wipe the area completely dry before applying new lubricant.

Step 2: Lubricating Hinges, Rollers, and Bearings

These are the workhorses of your garage door, enabling its movement. Proper garage door maintenance lubrication here is critical for smooth operation.

- Hinges:

- Locate the pivot points on each hinge (where the hinge bends).

- Spray a small amount of silicone lubricant or white lithium grease directly onto these pivot points.

- Wipe off any excess lubricant with a clean rag. The goal is a light coating, not a dripping mess that attracts dirt.

- Rollers:

- Metal Rollers with Ball Bearings: These are common and need attention. Spray lubricant directly into the ball bearings at the end of the roller shaft. You want to ensure the lubricant penetrates the bearings.

- Nylon Rollers: If your rollers have exposed metal stems, lubricate the stems where they meet the hinge. Avoid spraying the nylon wheel itself. Nylon is designed to be self-lubricating and adding grease can attract dirt, causing it to wear out faster.

- Once lubricated, open and close the door manually a few times to help work the lubricant into the bearings.

- Bearing Plates:

- These are the round plates located at each end of the torsion spring bar (above the center of the door).

- Apply a small amount of lubricant to the center of these plates, where the shaft passes through.

Step 3: How to Properly Lubricate Garage Door Springs

Springs are under extreme tension and are crucial for balancing your garage door. While they don’t move in the same way as rollers, they still benefit greatly from garage door maintenance lubrication.

- Torsion Springs:

- These are the large springs located horizontally above the garage door opening.

- Using your silicone spray, apply a light, even coat along the entire length of the torsion spring. You can shield the wall behind the spring with a piece of cardboard to prevent overspray.

- Once sprayed, use a rag to gently spread the lubricant evenly across the spring coils. This helps reduce friction between the coils as they expand and contract, prevents rust, and repels moisture.

- Extension Springs:

- These springs run parallel to the horizontal tracks on either side of the door.

- For extension springs, you should lubricate the pulleys, not the spring coils themselves. Spray the pulley bearings. Lubricating the springs themselves is generally not recommended as it can make them sticky and attract dirt.

- Wipe Excess Lubricant: As with other components, wipe off any obvious excess with a clean rag.

- Professional Spring Replacement: Garage door springs are extremely dangerous due to the high tension they are under. If your springs appear damaged, broken, or are making unusual noises even after lubrication, do not attempt to repair or replace them yourself. Always call a professional for garage door spring replacement.

Step 4: Lubricating the Opener Rail and Lock

Don’t forget these often-overlooked components during your garage door maintenance lubrication routine.

- Opener Rail:

- If you have a chain or belt-driven opener, the rail is where the trolley travels.

- Apply a light coat of silicone spray or white lithium grease to the top of the rail, where the trolley slides.

- Chain Drive:

- For chain-driven openers, apply a thin, even coat of white lithium grease or a specialized chain lubricant along the entire length of the chain.

- You can manually pull the emergency release and move the door a bit to help spread the lubricant. Wipe off any excess.

- Screw Drive:

- Screw-drive openers require specific screw drive grease. Apply this grease along the screw mechanism.

- Lock Mechanism:

- If your garage door has a manual lock, spray a small amount of silicone lubricant into the keyhole and work the lock mechanism a few times. This helps prevent sticking and rust in the internal components.

- For more detailed guidance on your specific opener type, consult your owner’s manual or check out our comprehensive garage door opener maintenance guide.

Your Lubrication Schedule and Troubleshooting

Regularity is key when it comes to garage door maintenance lubrication. It’s not a one-and-done task, but an ongoing commitment that pays off in the long run.

How Often to Lubricate and What Signs to Look For

- Frequency: As a general guideline, we recommend lubricating your garage door components every 3-6 months. For most homeowners in our service areas of St. Paul, Minneapolis, and Western WI, lubricating twice a year (once in the spring and again before winter sets in) is perfect. This prepares your door for seasonal changes and heavy use.

- Factors Influencing Frequency:

- Climate: Harsh winters, like those we experience in St. Paul, with extreme cold, snow, and ice, can put extra strain on your door and necessitate more frequent lubrication (every 2-3 months). Similarly, damp or salty climates (though less common inland) would also warrant more frequent attention.

- Door Usage: If your garage door is used frequently (e.g., multiple times a day as a main entry point), it will experience more wear and tear and benefit from more frequent lubrication.

- Door Age: Older doors might need more frequent attention as components age and wear.

- Signs Lubrication is Needed: Your garage door isn’t shy about telling you it needs some lube. Look out for these tell-tale signs:

- Squeaking or Grinding Noises: This is the most obvious indicator of excessive friction.

- Jerky or Hesitant Movement: If the door isn’t moving smoothly up and down, or seems to “catch” at certain points, it’s likely due to dry or sticky components.

- Visible Rust on Components: Rust indicates a lack of protection, and lubrication can help prevent further corrosion.

To Lube or Not to Lube: The Garage Door Tracks

This is a common point of confusion, and we’re here to clear it up:

- Do Not Lubricate Tracks: We cannot emphasize this enough – do not lubricate your garage door tracks! Lubricant on the tracks will attract dirt, dust, and debris like a magnet. This gunk will then build up, creating a sticky, abrasive mess that will actually hinder your rollers and cause them to bind or slip. It’s counterproductive and can lead to serious operational issues.

- Proper Maintenance: Instead of lubricating, your tracks need to be kept clean and clear.

- Clean Tracks with a Damp Rag: Regularly wipe down the inside of your tracks with a damp rag to remove any accumulated dirt, dust, or spiderwebs.

- Ensure They Are Dry and Clear of Obstructions: After cleaning, ensure the tracks are completely dry. Also, check for any physical obstructions, dents, or bends that might be impeding the rollers. For more general maintenance tips, you can refer to resources like How to Maintain a Garage Door.

Frequently Asked Questions about Garage Door Lubrication

We hear a lot of questions about garage door maintenance lubrication, so let’s tackle some of the most common ones.

What happens if I don’t lubricate my garage door?

Neglecting garage door maintenance lubrication is a recipe for trouble. Without that crucial protective layer, your door’s metal components will grind against each other, leading to increased friction and accelerated wear. This causes parts like rollers and springs to wear out prematurely, making your door noisy, inefficient, and difficult to operate. The added strain on your opener can cause it to fail sooner, and those minor squeaks can quickly escalate into expensive emergency repairs, or even a complete system failure that leaves your garage door stuck.

Can I use regular WD-40 on my garage door?

Absolutely not. This is a common misconception, but standard WD-40 is not a long-term lubricant suitable for garage doors. It’s primarily a water displacer and a light solvent. While it might temporarily silence a squeak, it will strip away any existing grease and quickly evaporate, leaving your components dry. Worse, it attracts dust and dirt, creating a sticky, abrasive film that can do more harm than good in the long run. Always use a silicone or lithium-based lubricant specifically designed for garage door components.

My garage door is still noisy after lubrication. What’s wrong?

If you’ve diligently performed garage door maintenance lubrication and your door is still making noise, it’s a strong indicator that the problem is more serious than just a lack of lubricant. The noise could be originating from:

- Worn-out Rollers: Rollers, especially plastic ones, can degrade over time. Metal rollers can have worn bearings.

- Misaligned Track: If the tracks are bent or not properly aligned, the rollers won’t move smoothly, causing friction and noise.

- Loose Hardware: Nuts, bolts, or screws on hinges, brackets, or the opener itself can come loose, leading to rattling or grinding sounds.

- Opener Problems: The garage door opener itself might be the source of the noise, particularly if it’s an older model or has internal issues.

- Worn Springs or Cables: Frayed cables or worn springs can also cause unusual noises.

In these cases, it’s best to have a professional inspect the door. Our experienced technicians can accurately diagnose the underlying issue and recommend the appropriate repair.

Keep Your Door Running Smoothly with Professional Maintenance

Proper garage door maintenance lubrication is a simple DIY task that delivers outsized benefits for performance and longevity. By following this guide, you can keep your door operating quietly and reliably while reducing the risk of surprise failures.

If you have already lubricated all key components and your door is still noisy, shaky, or unreliable, or if you would simply prefer a full professional tune-up, AA Garage Door is ready to help. Our team has provided fast, reliable service in the Twin Cities, St. Paul, and Western WI since 2001, with 24/7 emergency support, transparent pricing, and a satisfaction guarantee. For a comprehensive inspection, lubrication, and safety check, or for any garage door maintenance needs, reach out to our local experts today.