When Your Garage Ceiling Leaves No Room for a Standard Door

Low overhead garage door installation is the definitive solution for garages with limited vertical space—typically less than the standard 10-12 inches of headroom. If your home has low ceilings, overhead beams, or ductwork, you may think a sectional door is impossible. However, specialized hardware makes it feasible. For over 23 years, AA Garage Door LLC has provided expert professional garage door services across the Twin Cities, specializing in these complex installations. We find the right solution for the tightest spaces, ensuring safe, reliable operation.

Quick Answer: What You Need to Know

- Minimum Headroom Achievable: 4.5 inches for extension spring systems or 9.5 inches for torsion spring systems.

- Common Solutions: Double-track conversion kits, specialized top brackets, and rear-mount spring systems.

- Key Measurements Needed: Headroom, sideroom, and backroom.

- Best For: Garages with low ceilings, overhead beams, or structural obstructions.

- Installation Complexity: High—professional installation is strongly recommended for safety.

Older homes and basement garages often present low headroom challenges. Without enough clearance, a standard door won’t work. The good news is that you don’t have to compromise on a modern, functional sectional garage door. My team and I have installed countless low overhead systems where standard installation was not an option, guaranteeing long-term reliability.

Understanding Your Garage: Headroom and Why It Matters

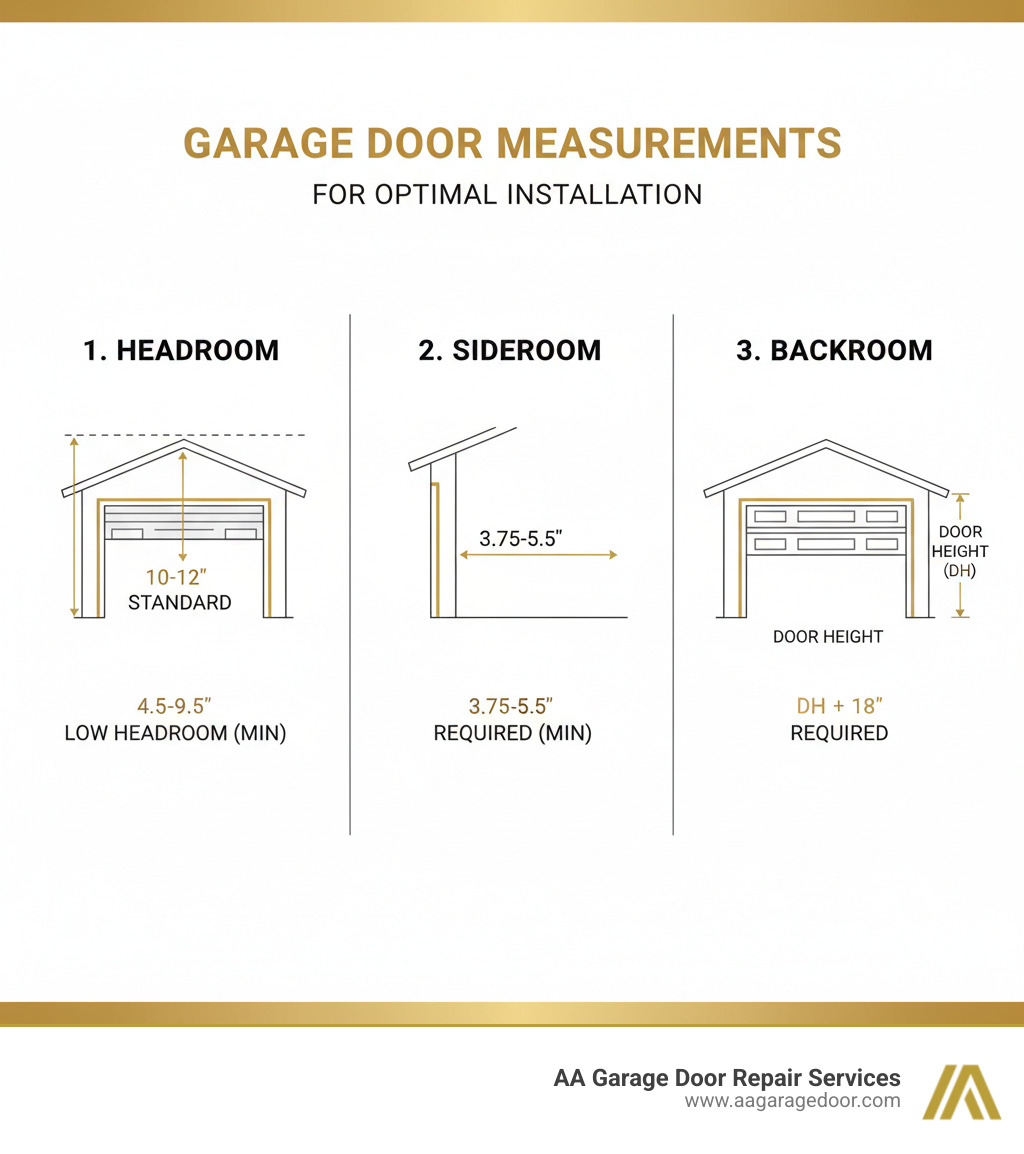

Before solving a low overhead garage door installation challenge, three critical measurements determine the necessary hardware.

- Headroom: The vertical distance from the top of the door opening to the lowest ceiling obstruction (e.g., beam, ductwork, or pipe). This is the most critical measurement.

- Sideroom: The horizontal space from the side of the door opening to the nearest wall. This area is needed for mounting the vertical tracks.

- Backroom: The depth from the door opening to the rear wall of the garage. It must accommodate the horizontal tracks and opener.

Why You Might Need a Low Headroom Solution

Standard garage doors require significant clearance: 12 inches of headroom for a torsion spring system and 10 inches for an extension spring system. This space allows the top door panel to transition smoothly onto the horizontal tracks. Many garages, especially in older homes, basements, or renovated spaces, lack this clearance due to:

- Overhead support beams

- HVAC ductwork

- Plumbing or electrical conduits

- Low-built ceilings (common in certain construction eras)

Without adequate clearance, a standard door will fail to open or cause structural damage. This is precisely why specialized low headroom systems were invented.

How to Correctly Measure Your Garage Space

Accurate measurements are non-negotiable. A small error can lead to a non-functional door.

- Measure Headroom: From the top of the finished door opening, measure straight up to the lowest obstruction. Check at several points across the opening and use the smallest measurement as your true headroom.

- Measure Sideroom: Measure from the side of the door jamb to the nearest wall on both sides. Standard systems need 3.75 to 5.5 inches.

- Measure Backroom: Measure from the door opening to the back wall. You need the door’s height plus at least 18 inches for the tracks and opener.

These three measurements form the blueprint for a successful low headroom installation, telling us exactly which solutions are viable for your space.

Common Low Headroom Solutions and Hardware

When standard clearance is unavailable, we use specialized hardware designed for tight spaces. These systems create a more compact transition for the door, allowing it to operate with minimal vertical space.

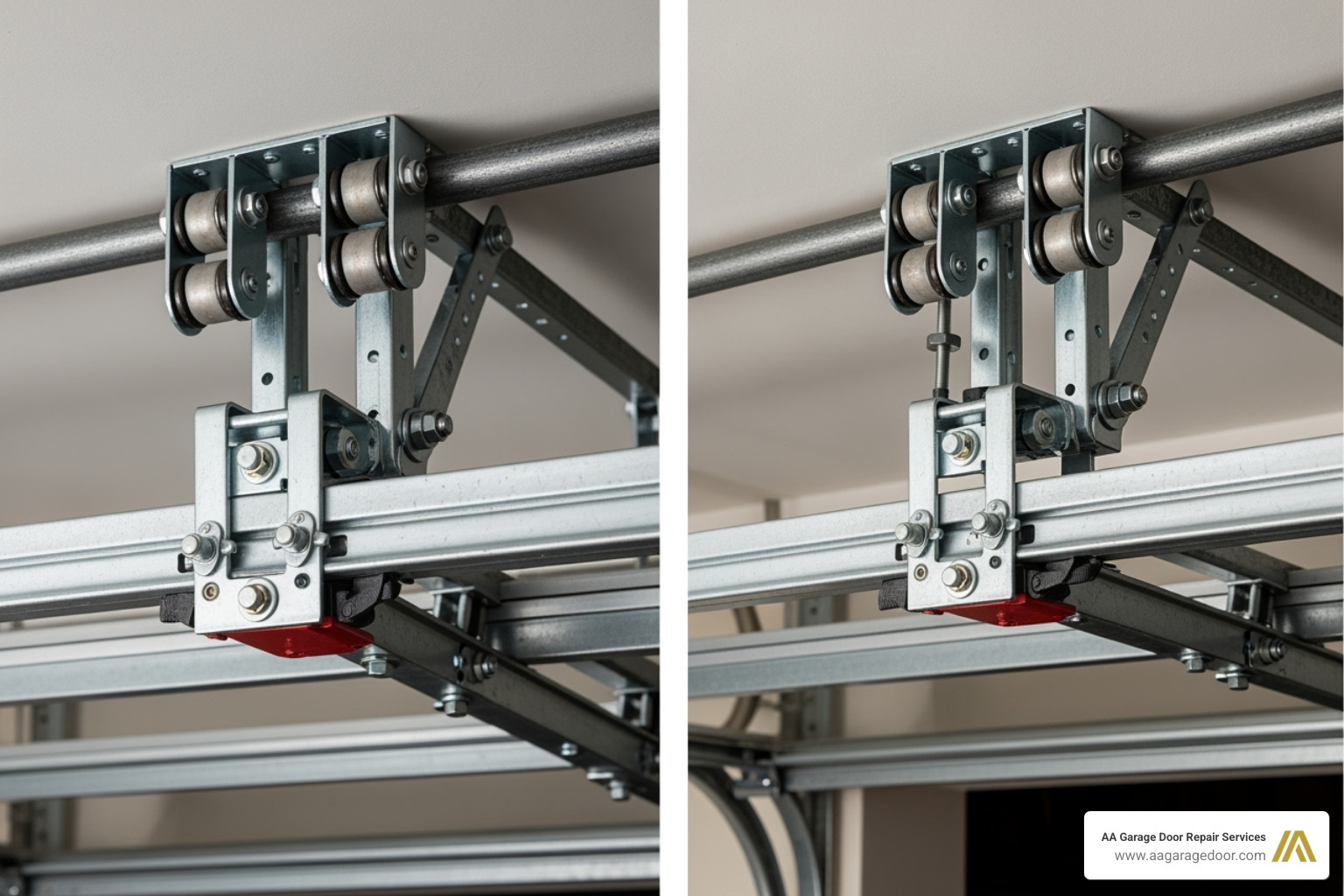

- Double-Track Systems: This is a highly reliable solution that uses two stacked horizontal tracks. The top door panel follows the upper track while the other panels use the lower one. This dual-path design creates a much tighter turn, reducing headroom needs to as little as 4.5 inches for extension springs or 9.5 inches for torsion springs.

- Rear-Mount Torsion Springs: When headroom is limited but backroom is plentiful, the entire spring assembly can be moved to the back of the horizontal tracks. This frees up critical overhead space above the door opening.

- Specialized Top Brackets: Also known as quick-close fixtures or rapid flex brackets, these custom-engineered components allow the top roller to pivot inward more quickly. This action helps the door transition from vertical to horizontal movement in a much smaller space. Some systems, like “Super Sneaky Low Overhead Door Products,” can operate in 6 inches of headroom or less.

These solutions make it possible to install modern, reliable sectional doors in garages previously considered unsuitable.

Comparing Hardware: Double Track vs. Specialized Low Headroom Kits

Choosing between a double-track system and a specialized hardware kit depends on your garage, budget, and preferences.

Double-track systems are a proven, robust solution. They use more hardware but are highly reliable and compatible with most sectional steel doors. The main trade-off is aesthetic, as the two tracks create a more industrial look. Conversion kits are often budget-friendly, typically costing between $100 and $300 for the hardware.

Specialized low headroom hardware (like Super Sneaky) modifies the door’s movement using unique hinges and roller setups on a single track. This creates a cleaner, less cluttered appearance and can sometimes achieve even lower clearances (down to 6 inches). However, these proprietary systems can be more expensive and require extremely precise installation.

Both systems are highly effective at solving low headroom problems. The best choice depends on a careful assessment of your garage’s specific dimensions and your project goals. One unavoidable trade-off with both systems is a slight reduction in the clear opening height, typically around 6 inches, because the top of the door hangs lower when fully open. When you call us at (651) 702-1420, we’ll assess your situation and recommend the best approach for your space and budget.

Your Guide to Low Overhead Garage Door Installation

Installing a low overhead garage door installation system is a technically demanding project where safety and precision are paramount. It transforms how a door operates, requiring a fundamental rethinking of its components.

Safety Precautions: Our Golden Rules

Safety is the first priority. We always follow these rules:

- Disconnect Power: Cut power to the opener at the circuit breaker to prevent accidental activation.

- Secure the Door: If modifying an existing door, clamp it securely to prevent it from falling. A garage door can weigh up to 400 pounds.

- Use Protective Gear: Safety glasses and work gloves are essential to protect against flying metal shards and moving parts.

- Follow Instructions: Each low headroom kit has unique requirements. The manufacturer’s manual is the blueprint for a safe installation.

Modifying Tracks and Installing a Conversion Kit

A low headroom conversion involves several key modifications. Vertical tracks are often cut to a specific length, and new mounting holes are drilled. For double-track systems, a second upper horizontal track is added. Specialized hardware, including flag brackets and quick-close top fixtures, is installed to create the tighter turning radius. A typical conversion kit includes:

- Low headroom top brackets

- New or modified horizontal tracks

- Specialized flag brackets and safety bottom brackets

- All necessary fasteners and reinforcement plates

- Detailed installation instructions

For general information on opener installation, Home Depot’s guide offers a good overview, but low headroom jobs often require specific opener types and modifications.

Essential Tools and Materials

A successful installation requires the right tools. A comprehensive toolkit includes a wrench set, drill, a level (critical for alignment), tape measure, vise grips, and a hacksaw or angle grinder for track modification. In addition to the conversion kit, we recommend installing new high-quality rollers and using a lithium-based garage door lubricant to ensure smooth, quiet operation.

Step-by-Step: Installing a Double-Track Conversion Kit

While specific steps vary by manufacturer, the general process for a double-track conversion is as follows:

- Track Preparation: The existing vertical tracks are precisely cut and drilled to accommodate the new hardware.

- Track Assembly: The modified vertical tracks and new double horizontal tracks are assembled with specialized flag brackets, ensuring everything is perfectly plumb and level.

- Door Section Installation: The door sections are installed one by one, with rollers inserted into the tracks and hinges connected.

- Top Fixture Attachment: The special low headroom top brackets are attached to the top panel. These fixtures are crucial for creating the tight curve.

- Spring System Connection: This is the most dangerous step and requires professional expertise. The lift cables and springs (extension or torsion) are connected and properly tensioned. For extension springs, safety containment cables are mandatory.

- Final Adjustments and Testing: The door’s balance is tested and adjusted until it stays in place when opened halfway. All moving parts are lubricated, and the door’s operation is tested manually and with the opener.

This methodical process ensures your low headroom door operates safely and reliably. For more on what to expect during a typical project, see our guide on what to expect during garage door installation.

Key Considerations for Low Headroom Systems

While a low overhead garage door installation solves a major problem, it’s important to understand the trade-offs. The primary advantage is enabling a sectional door in a space where it would otherwise be impossible. However, these systems are more complex and costly than standard installations.

A key consideration is that the clear opening height of your garage door may be reduced by about 6 inches when fully open. The door’s top section hangs slightly lower to accommodate the tighter track curve. This is a critical factor if you own a tall vehicle.

Impact on Garage Door Openers

Your choice of opener is crucial for low headroom systems.

- Side-Mount (Jackshaft) Openers: These are the gold standard for low headroom applications. They mount on the wall next to the door, connecting directly to the torsion bar and eliminating any overhead hardware. This makes them ideal for extremely tight spaces.

- Traditional Drawbar Openers: These can sometimes be used but may require special operator extension brackets. You must ensure there is enough clearance for the opener rail and arm to function without interference.

Many modern smart openers are compatible with both types. For more on this technology, check out our Smart Garage Door Installation Complete Guide.

Door Model Limitations

Low headroom hardware works best with specific door types. For optimal performance, we recommend doors with individual panel sections of 21 inches high or less. Taller panels struggle with the tight curve. Most residential kits are designed for doors up to 8 feet tall. While many kits are designed for steel sectional doors, wood doors can often be accommodated with different hardware, though their weight and rigidity require special consideration.

Safety and Maintenance for Low Headroom Doors

Safety and maintenance are even more critical for low headroom systems due to their tighter tolerances.

- Proper Spring Tension: The unique geometry requires precise spring balancing. Incorrect tension is extremely dangerous, which is a primary reason professional installation is recommended.

- Smooth Roller Movement: High-quality steel or nylon rollers are essential to handle the tighter turns without binding.

- Regular Maintenance: We recommend visual inspections every few months. Check for loose fasteners and wear on rollers and hinges. Both tracks in a double-track system must be kept clean and lubricated with a quality silicone or lithium-based grease. The specialized top brackets require particular attention to ensure they pivot freely.

These systems may experience slightly accelerated wear on rollers and hinges due to increased friction. If you notice grinding sounds or jerky movements, seek professional service immediately, as small problems can escalate quickly in these tightly-calibrated systems.

The Role of Professional Help in Low Overhead Garage Door Installation

When it comes to low overhead garage door installation, this is a project best left to professionals. The complexity and inherent dangers, particularly with spring systems, make it a risky DIY endeavor.

DIY vs. Professional Installation: Why Expertise Matters

The number one reason to hire a professional is safety. Garage door springs are under extreme tension and can cause severe or fatal injuries if mishandled. Low headroom systems add layers of complexity, from modified track geometry to specialized hardware that requires precise adjustment to achieve proper balance. An improperly balanced door can crash down or bind in the tracks.

Beyond safety, professional expertise ensures the job is done correctly. A pro can achieve the fine-tuned balance needed for a door with a unique track configuration, ensuring smooth, long-lasting operation. Furthermore, most manufacturer warranties are voided if the door is not installed by a certified technician, so professional installation protects your investment.

Cost of Professional Installation

Professional low overhead garage door installation costs more than a standard job due to the specialized hardware and additional labor. However, this investment covers expertise, specialized tools, and safety assurance. When you factor in the risks of injury, the cost of tools, and the potential for costly mistakes, professional installation is often the more economical choice in the long run.

Finding a Qualified Installer

Not all garage door companies are experienced with low headroom systems. It’s crucial to find a technician who understands the unique challenges. When searching for an installer in areas like Hudson, WI, or the Twin Cities metro, look for a company with proven expertise.

Since 2001, AA Garage Door has specialized in solving these tough installation challenges. A qualified installer should have:

- Extensive experience with low headroom systems.

- Certified and insured technicians.

- Transparent pricing and detailed estimates.

- A strong local reputation with verified reviews.

Frequently Asked Questions about Low Headroom Installations

We often get asked specific questions about low headroom garage door installations. Here are some of the most common ones, answered directly:

What is the absolute minimum headroom for a garage door?

Standard doors typically require 10 to 12 inches of headroom. However, with specialized low headroom kits, this requirement can be significantly reduced. For extension spring systems, the absolute minimum headroom can be as little as 4.5 inches. For torsion spring systems, it’s typically around 9.5 inches. Some ultra-low systems, like certain “Super Sneaky” products, can even function in 6 inches of headroom or less.

Does a low headroom kit reduce my garage door’s opening height?

Yes, in many cases, a low headroom installation will cause the top section of the door to hang slightly lower when fully open. This typically reduces the clear opening height by about 6 inches. For example, a 7-foot high door with a low headroom system might have an actual vehicle clearance of 6 feet 6 inches. This is an important consideration if you have a taller vehicle, such as a truck with a roof rack, that barely clears your current opening.

Can I use any garage door opener with a low headroom system?

Not always. While many standard drawbar openers can be adapted with specialized operator extension brackets, they still require the rail and motor to be mounted overhead. For extremely low headroom situations, a side-mount (jackshaft) opener is often the ideal solution. These openers mount to the wall beside the door, completely avoiding overhead space issues and providing the maximum possible overhead clearance. If using a drawbar opener, ensure the opener arm and the unit itself will clear the door and tracks when the door is fully open.

Get Your Low Headroom Challenge Solved

Navigating the complexities of a low overhead garage door installation is achievable with the right professional assistance. We’ve shown how specialized hardware like double-track systems can make a sectional door possible even in the tightest spaces. The key takeaways are the critical importance of accurate measurements, understanding the trade-offs, and recognizing the value of professional expertise for a safe and reliable outcome.

The benefits of a low headroom system—enabling installation where it otherwise wouldn’t be possible—far outweigh the challenges when handled correctly. However, the intricate nature of these installations, especially handling high-tension springs, underscores why this is a job for experienced technicians.

For expert assistance with your low overhead garage door installation in the Twin Cities, including St. Paul, Woodbury, and surrounding areas, or in Western WI locations like Baldwin and Hudson, trust our experienced team at AA Garage Door. We are dedicated to providing safe, reliable, and efficient solutions custom to your home’s unique needs.

Don’t let a low ceiling limit your options. Request a quote for your garage door replacement online, and let us help you find the perfect low headroom solution for your home.